What can you do with old laser tubes

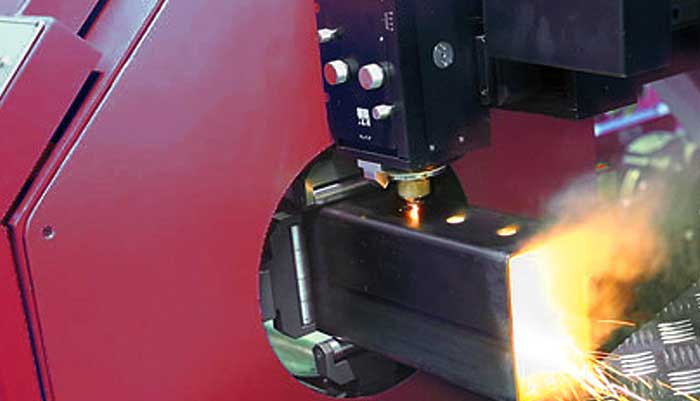

Whether it is the manufacture of specific equipment for gyms, or smaller, multifunctional exercise machines for domestic spaces, tubes are the fundamental building blocks. This is why tube processing technologies, such as bending and laser cutting, are so widely used in this sector.

Find laser systems for electronics production that can perform high-precision, fast cutting, welding, marking and ablation of metals or plastics.